3D printing and other updates

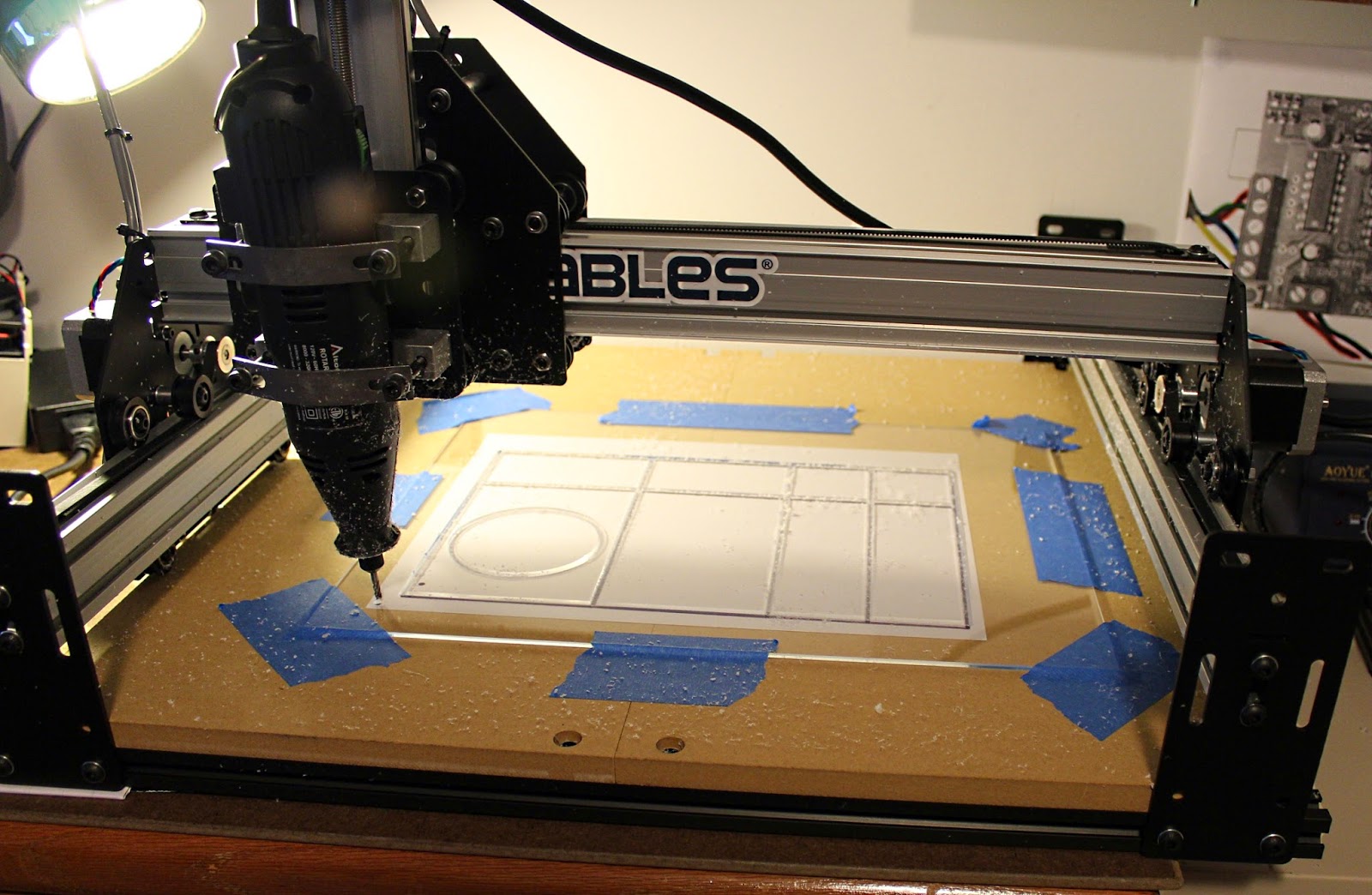

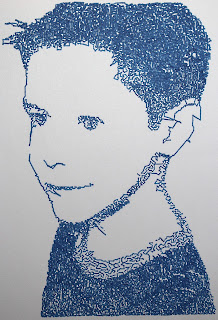

I haven't blogged in a while, but that doesn't mean I have been idle. Here are a few updates: I've updated my CNC setup with a Makita router I've ground out a few interesting works on the CNC (more later) I've created a robot that runs off of an Arduino and a Tamiya "tank" frame I've gotten a 3D printer This last one has been a lot of fun. I'll get into all these points eventually (maybe in different posts), but I wanted to throw in a few notes about the 3D printer first. A few years back, my wife had started work as a technical para-professional at our kids' elementary school. A para-professional is anyone who has some expertise with a particular subject, but is not a full-time teacher. Her job description included things like help with tech-support, assist in standardized testing setup and handling, as well as help teach kids how to code or use computers and related tech. She worked as a tech-para a couple of years until the di...